One of the materials that we work with at S&S Optical is borosilicate glass. The main components of borosilicate glass are boron trioxide and silica. This composition makes borosilicate glass much more tolerant of extreme temperature changes than other types of glass. While borosilicate has many names, most people would recognize Pyrex instantly, the trade name under which many dishes that are made using borosilicate glass are sold.

Borosilicate glass has uses in many different industries and applications. In health and science facilities, most labware is made using borosilicate because of its clarity and resistance to thermal shock. In specialized applications, borosilicate glass may also be used because of its chemical resistance.

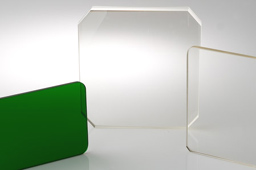

At S&S Optical, we fabricate high quality custom borosilicate glass parts. For industrial or commercial applications with specific requirements, we can cut, shape, drill, bevel, grind & polish and more. If you’re looking for a prototype of your borosilicate part before we begin high volume production, we can take your specifications and create a functional component for you to test in your application.

Industries Served

S&S Optical has served many industries, including:

- Aerospace

- Automotive

- Lighting

- Marine

- Medical

- Optical

Our customers trust us to fabricate quality glass and quartz parts for them. With over 50 years of experience as an optics manufacturer and a skilled team of experts, we are capable of producing even the most complex parts for your application. Our state-of-the-art facility is equipped with the latest machinery and tools to fabricate custom parts from glass and quartz. Whether you are looking for borosilicate or parts made using other materials, contact us or request a quote today.